Isotec® TBX insulated containers

Do you need to transport goods at a constant temperature without breaking a secure cold chain during transportation? The Isotec® TBX insulated container from GEBHARDT is your guarantee of freshness!

Do you need to transport goods at a constant temperature without breaking a secure cold chain during transportation? The Isotec® TBX insulated container from GEBHARDT is your guarantee of freshness!

With the Isotec® TBX thermal container from GEBHARDT, you are choosing a high-quality and durable product for temperature-controlled transport in logistics. The premium-quality load carrier makes it easier for you to transport temperature-sensitive and perishable goods under refrigeration.

The insulated container from GEBHARDT is "made in Germany" and guarantees the secure cold chain, as well as safer and more stable transport for your fresh and frozen food. Instead of expensive refrigerated lorries or refrigerated transport companies, use the GEBHARDT insulated container with conventional lorries to deliver food with different temperature zones in a single truck delivery.

With GEBHARDT as the market leader for logistics solutions, you have the specialists for load carriers and efficient logistics processes at your side. You can rely on the quality of our products!

The using of refrigerated trucks: Save energy and fuel by cooling your truck to just 3°C to 8°C instead of -21°C. The using of dry trucks: By using passively cooled thermal containers, you have no cooling costs or maintenance costs for an additional truck refrigeration unit and still deliver with the secure cold chain.

By using insulated containers, it is possible to transport frozen and fresh goods in the same hold. The better utilisation of the cargo space allows you to get more flexibility and helps you to save costs through the combined transport of goods.

The procurement of dry ice can be difficult and expensive, especially in the summer months. Price fluctuations and the limited availability of dry ice lead to a risky cold chain. Reusable eutectic plates, on the other hand, pay for themselves very quickly and reliably guarantee you the secure cold chain.

By using reusable eutectic plates, you can significantly improve your carbon footprint. By dispensing with dry ice and deep-freeze trucks, reduce your fuel and energy consumption and make your contribution to greater sustainability in logistics.

Isotec® TBX insulated containers are available in a range of variants to help optimise your logistics processes and procedures. To find the most appropriate insulated container for your logistics processes, our insulated containers are available in a range of sizes and versions.

Do you deliver to small branch stores in narrow streets but your products have to stay fresh over the last mile? Not a problem. Our rollable thermal containers make the last stretch to unloading extremely easy. Tight turns in narrow streets, alleys and corridors are not problem at all due to fitted swivel and fixed castors.

Do you deliver to large stores and use materials handling equipment in your logistics procedures? In which case, the Isotec® TBX insulated container with pallet base is the right choice for you! Specifically optimised for use with material handling equipment, the GEBHARDT insulated container can be accessed from all four sides by forklift trucks and electric or hand-driven pallet jacks – perfect for use in large logistics businesses with material handling equipment.

| TBX on rollers (Ø 125mm) | Volume | Payload | External Dimensions | Internal Dimensions |

|---|---|---|---|---|

| 410 | 410 Liter | 500 kg | 580 x 803 x 1806 mm | 431 x 625 x 1425 mm |

| 600 | 600 Liter | 500 kg | 757 x 818 x 1773 mm | 609 x 659 x 1416 mm |

| 725 | 725 Liter | 500 kg | 757 x 948 x 1773 mm | 604 x 809 x 1407 mm |

| 795 | 795 Liter | 500 kg | 757 x 948 x 1936.5 mm | 604 x 811 x 1570 mm |

| TBX on pallet | Volume | Payload | External Dimensions | Internal Dimensions |

|---|---|---|---|---|

| 900 | 900 Liter | 700 kg | 797 x 1198 x 1788 mm | 611 x 1025 x 1444 mm |

| 1000 | 1000 Liter | 700 kg | 797 x 1198 x 1888 mm | 611 x 1025 x 1544 mm |

| 1070 | 1070 Liter | 700 kg | 797 x 1198 x 1988 mm | 611 x 1025 x 1644 mm |

| 1170 | 1170 Liter | 700 kg | 797 x 1198 x 2138 mm | 611 x 1025 x 1794 mm |

Optionally, the GEBHARDT thermal container is available with various accessories and different equipment options!

Because our Isotainer makes it possible to ensure temperature-controlled transport, we guarantee the transport of your perishable food with the Isotec® TBX without interrupting the cold chain. Wondering how this works? Thanks to the insulating outer walls, in conjunction with the use of eutectic plates (cold packs) or dry ice, the cold storage cold can be stored inside the load carrier. Your goods can be transported in our thermal container at their optimal temperature for a period of up to 24 hours without interrupting the cold chain. The freshness of your food or medical products is maintained throughout the entire transport route.

As standard, we install impact and collision protection on our containers to prevent damage. This impact and collision protection made of galvanized sheet metal is the solution to prevent damage during logistics processes and serves as a stable buffer. The long service life of our containers is due, among other things, to this protective measure, which optimally protects the insulating outer skin of the container from cracks or abrasions. Another big advantage of our containers is their low weight, which makes handling much easier. The combination of built-in aluminum and steel contributes to the low weight of our thermal containers and means cost savings for you during transport.

Using eutectic plates instead of dry ice cooling can save you a lot of money. The eutectic plates are reusable, recyclable, stable and safe to use. Their filling consists of a non-toxic filling of salt and water, which means that the delivered goods can be cooled in a food-safe manner. The eutectic plates are an excellent replacement for expensive dry ice and are considered a sustainable and cost-effective way of cooling in the long term.

Eutectic plates are considered an absolutely reliable form of cooling. Depending on what type of goods you want to transport, you can choose between different temperature ranges and melting points for our panels. Regardless of whether you want to transport frozen goods, meat products, baked goods, fish, pharmaceuticals or fresh goods at neutral room temperature such as fruit or vegetables, you will find the right eutectic plates or ice packs for every purpose in our product range. The eutectic plates, also known to the layman as ice packs, are available with different melting points and sizes.

To ensure that our thermal containers are optimally suited for your purposes, we will be happy to advise you individually. Our thermal containers promise transport with a secure cold chain. Let our thermal specialists at GEBHARDT show you the functionality of the containers in a guided test.

The GEBHARDT isothermal container is suitable for use in a wide range of industries and can be used wherever perishable or temperature-sensitive goods are transported.

Do you have any questions about the GEBHARDT insulated container or would you like individual advice? Please feel free to contact us!

These products could also be interesting for you!

Our innovative and well thought out thermal container is the lightest in its class and gains approval through its extremely light weight and the ergonomic design of all its handles. From an economic and ecological perspective, our reusable containers have been designed to provide many years of efficient use.

Our containers can cope with (almost) any temperature range. They can be used to transport fresh products such as fruit or vegetables as well as frozen goods. In addition to fresh goods and goods from the freezer, our thermal containers are also used in butchers, bakeries, wholesale fish markets, catering, gastro as well as to transport dry ice. Medicinal products which require refrigerated transportation can also be transported using the Isotec® TBX without any problems. The quality and easy handling of our GEBHARDT insulated containers means they can be used in many different application areas.

Standard Euro containers (e.g. E1, E2, E3) can be accommodated in every TBX size. The size of the tub has been re-engineered in our new generation of containers to make handling even easier for our customers and to increase the efficiency of their transportation processes. The internal dimensions of the container have been adapted to match common box sizes and thus allow you to transport your goods securely and efficiently.

Our isocontainers come as standard in blue. Obviously we can accommodate your specific colour requirements and match the bodyshell of the container to your corporate livery. Add your logo to the thermal container? No problem. We can produce your container to match your corporate identity.

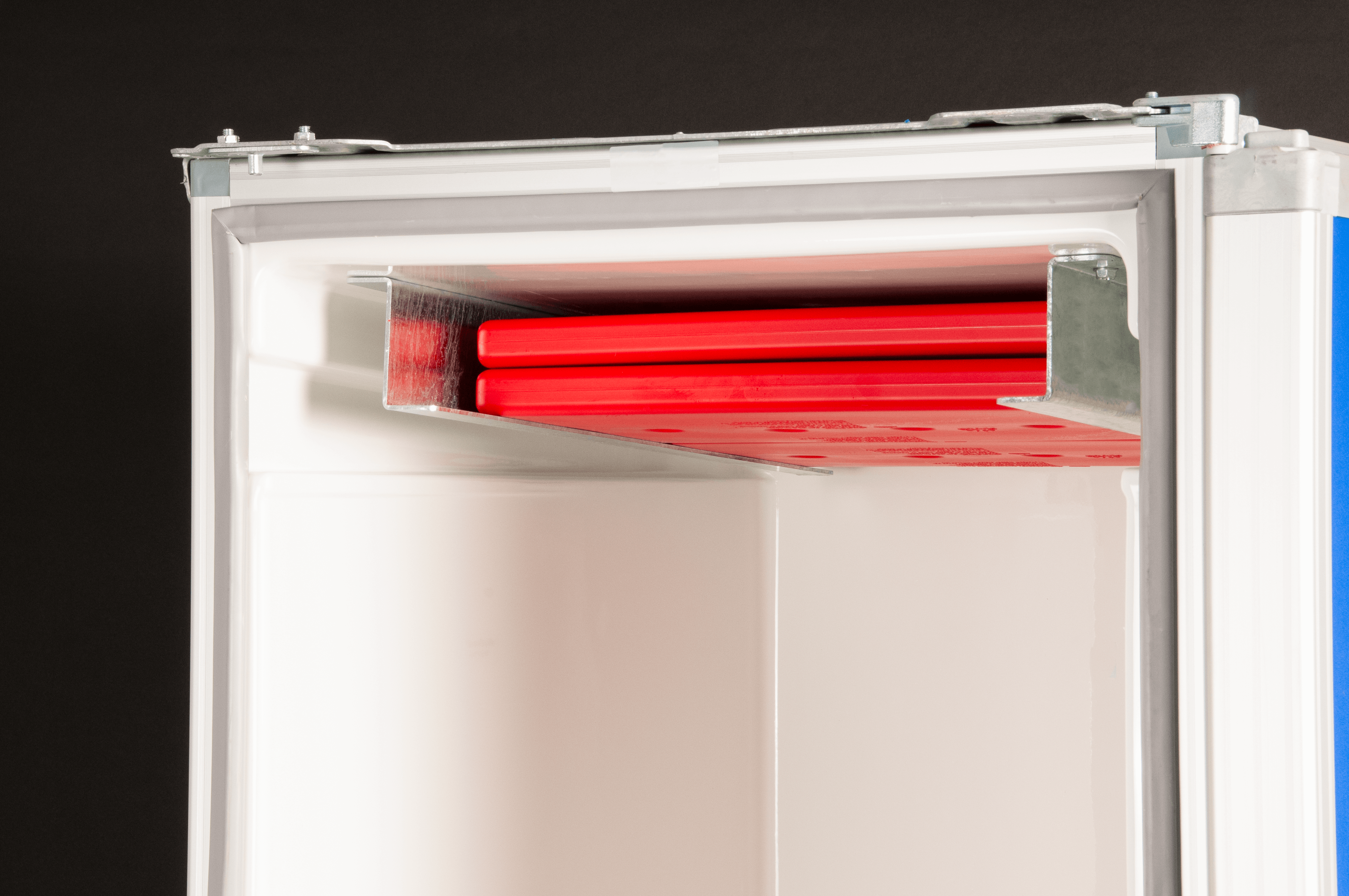

There are no limits to the flexibility of our GEBHARDT insulated containers. If you need a GEBHARDT insulated container with eutectic cooling, slide bars are almost essential to support the eutectic plates. The stable slide bars made from hot-dip galvanized steel are located at the top of our isothermal containers and can accommodate up to six eutectic plates. If you decide to include a shelf for the eutectic plates, it is inserted in the top of the container and provides support for the eutectic plates together with eutectic cooling. This type of shelf is not for use as storage: its sole function is to support eutectic plates You can cool our thermal containers with either eutectic plates or dry ice. If you decide to use dry ice cooling for your logistics processes instead of eutectic cooling, this shelf is the perfect solution for your dry ice. Further load-bearing shelves can be added as an extra storage level. Depending on the size of the container, inner tubs are available with several storage levels.

As our insulated containers have a lifespan of many years, it is important to us that our insulated containers are easy to repair. We offer our customers a 24-month guarantee on purchased containers. Significant damage is, however, extremely rare due to their stable design. If you have a few minor problems with your containers despite this, any repair services will be assessed within a few days. Many components can be easily replaced due to individual seam and screw fastenings. Our focus is always on quick, customer-oriented problem solving.

Cleaning our containers is extremely easy. Whether by hand, with a pressure washer or in an automated washing system, dirt deposits are easily removed from our isocontainers at very little cost. The cleaning material best suited to our containers is CF315 from Calvatis which easily removes deposits without attacking the container’s tub. It also does not alter the appearance, even after multiple cleaning operations. Water ingress into the insulation layer is prevented by the container’s unique construction.

The duration of cooling depends on a range of factors and cannot be categorically stated. Product composition, filling degree and precooling of the container are decisive factors for the duration of cooling. We would be happy to complete a calculation of the temperature profile specifically for you based on your data and discuss it with you further. Opening the doors frequently or leaving them open for extended periods during transportation has an effect on the temperature in the container. The number of times doors are opened and the temperature profiles this produces can be captured and documented with an intelligent tracking system from 4smartlogistics. An ideal scenario for complete digital data capture to analyse and optimise your logistics processes.

The duration of precooling for our insulated containers depends on the goods to be transported. For fresh goods, the temperature is from 0°C to 2°C, while for frozen goods, it is between -21°C and -25°C. We recommend a precooling time of 12 to 20 hours to our customers in order to meet the high quality standards of your products. GEBHARDT insulated containers allow you to transport goods for up to 24 hours without breaking the cold chain – this is our freshness guarantee!

Our eutectic plates (cold packs) represent significant cost savings compared to dry ice. The eutectic plates are reusable and inexpensive to purchase. You will be amazed at the savings potential compared to dry ice. Our eutectic plates are available in a range of melting points and sizes and are therefore suitable for many different purposes in cold chain logistics.

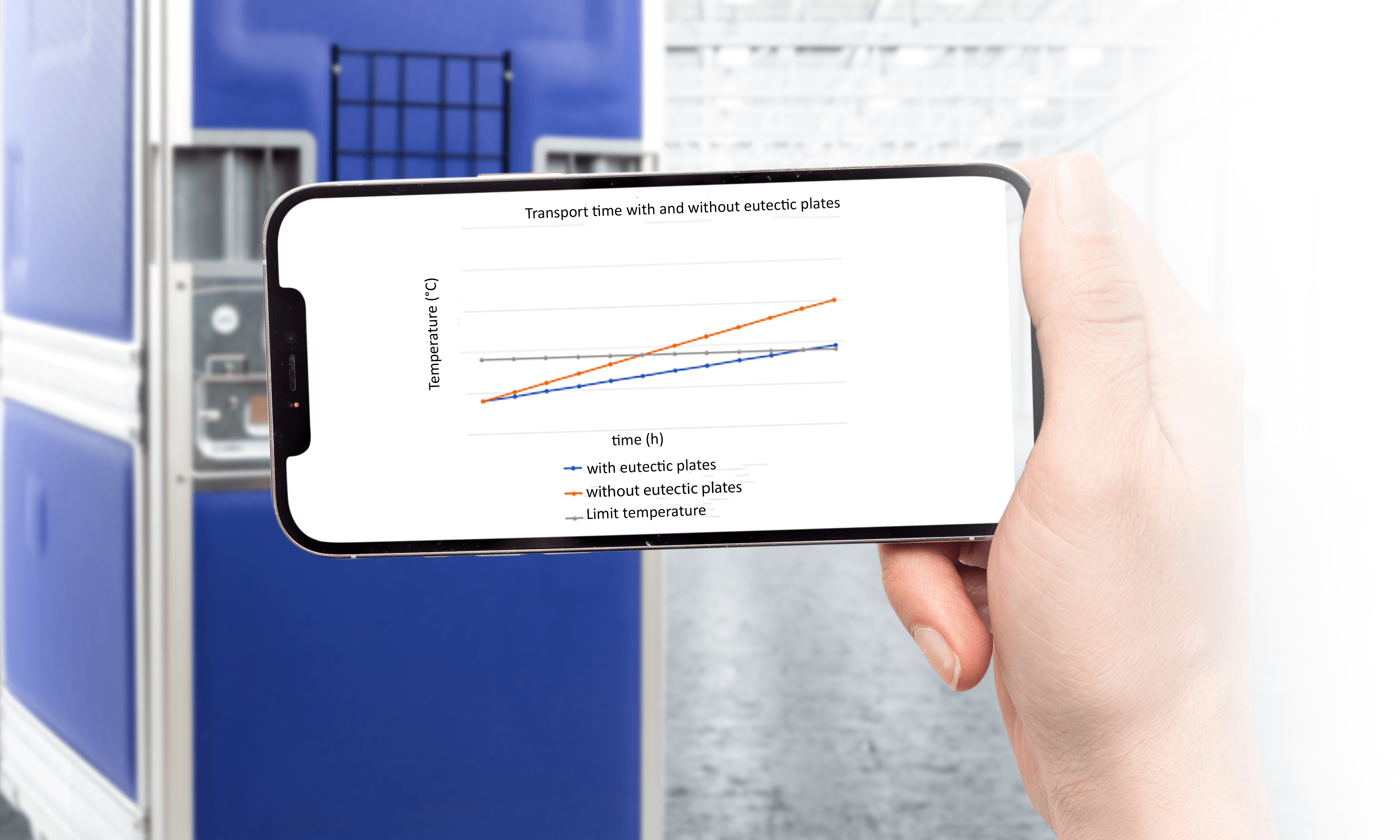

Here is a brief explanation of how they work: the eutectic plates (cold packs) must be deep-frozen for them to function correctly. It should be noted that the cooling capacity is only achieved if the plates are completely frozen. Freezing the eutectic plates stores cold energy. The cold is continuously released during transportation and thus prevents the internal temperature of the insulated container rising. This keeps your goods fresh for longer and you can transport your goods in a secure cold chain until the threshold temperature is reached. GEBHARDT insulated containers guarantee a secure cold chain is maintained for up to 24 hours. Our thermal specialists will happily complete a specific thermal analysis for you to determine the precise number of eutectic plates for your application and the relevant transportation time.

The freezing time depends on the melting point of the eutectic plates and the freezing temperature. Depending on the temperature, the freezing time can be from 15 to 21 hours. For example, a eutectic plate with a melting point of -21°C needs 19 hours to freeze completely at a temperature of -26°C. We generally recommend you select a freezing temperature at least 5°C less than the melting temperature of the eutectic plate.

Our insulated containers can be fitted or retrofitted at any time with a range of accessories. In addition to slide bars to support eutectic plates, we also offer individual shelves to carry goods or support eutectic plates or for cooling with dry ice. There is also an option to order containers with a tub with grooves to accommodate shelves. In addition to this, you can also supplement your order with transparent pockets, an extra lever or an external thermometer to display the internal temperature.

The manufacturing processes and our insulated containers are regularly certified by an external testing body of our partner DNVGL in accordance with ATP and HACCP requirements. This ensures that you can use our isocontainers to safely transport your loose and packaged foodstuffs. Our GEBHARDT insulated containers ensure foodstuffs are transported safely and to high quality standards.