GEBHARDT load carrier for assembly components

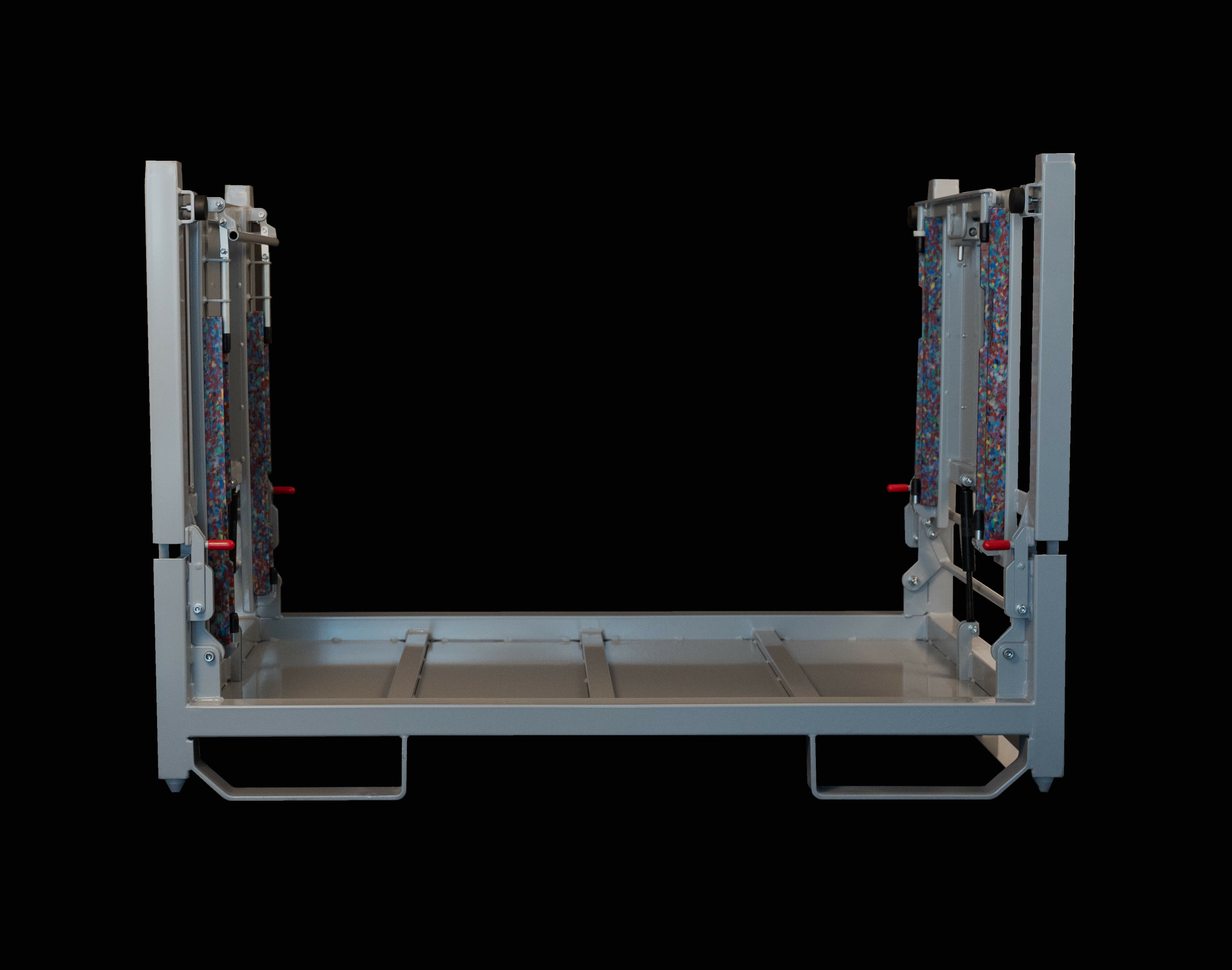

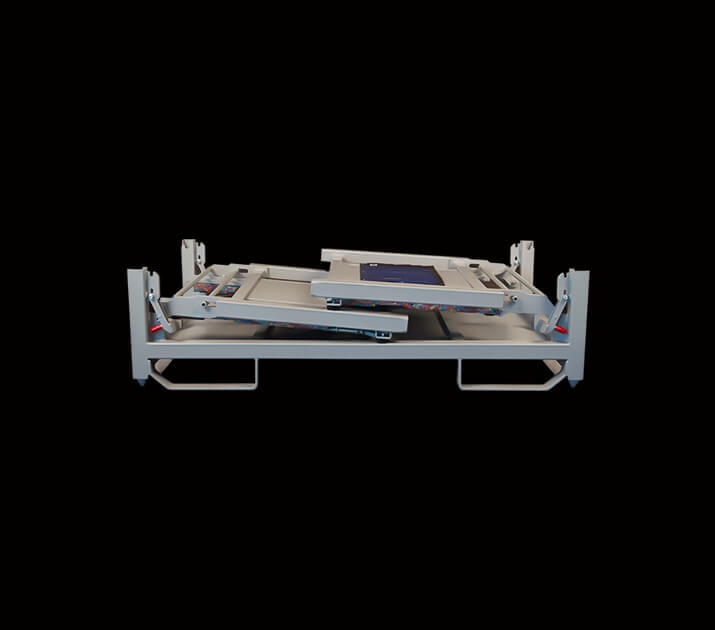

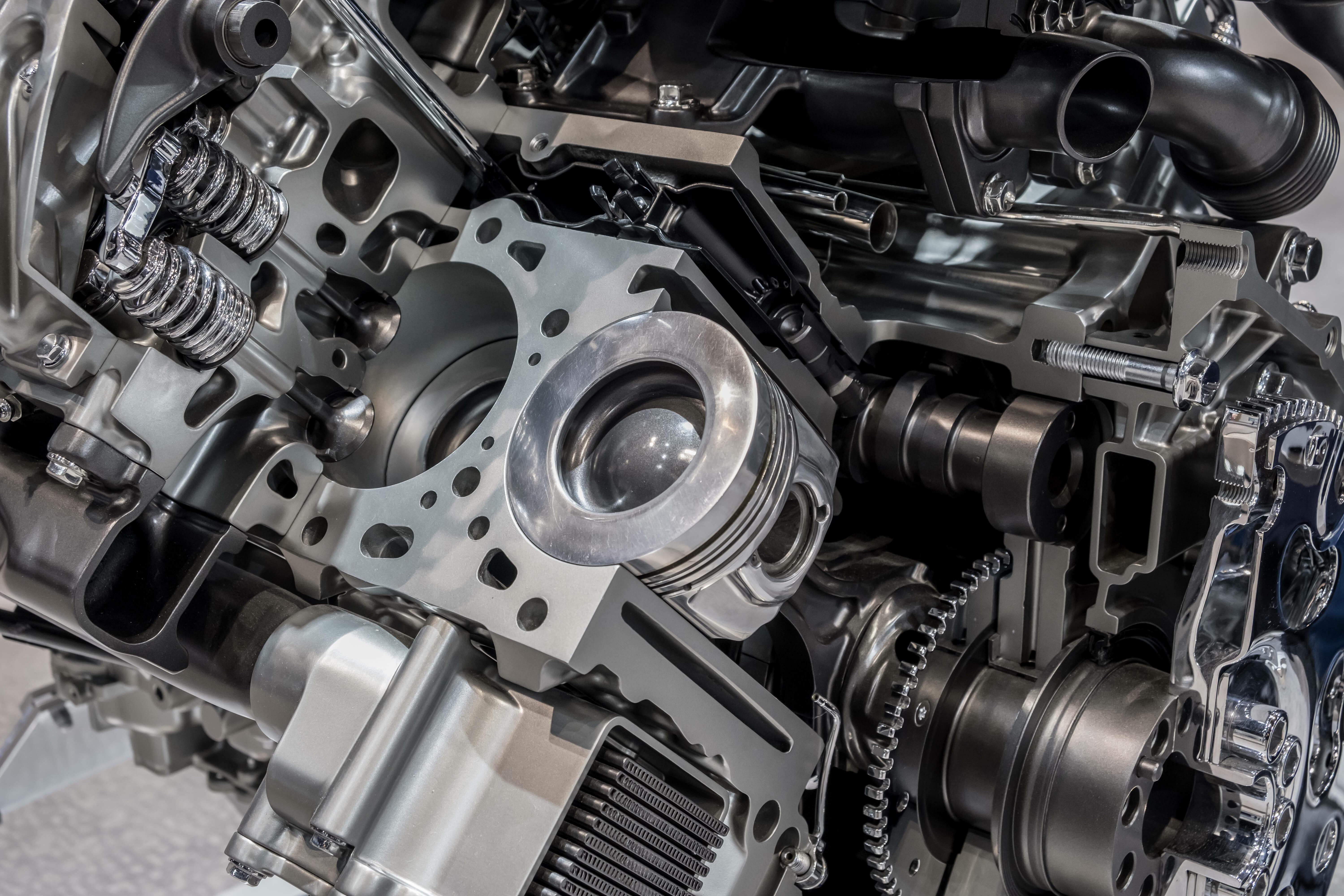

The transport and storage of highly sensitive assembly components in the automotive industry must meet the highest requirements for safety, precision and accuracy of fit. For this reason, there is no standard in GEBHARDT special load carriers, but consistently individual, customized load carriers for the special requirements of our customers.

Load carriers individually developed for your processes and products optimally protect your goods during transport and can be easily integrated into existing logistics processes. GEBHARDT special load carriers are manufactured in series production with the highest standards of precision and are suitable as automatable load carriers for use with robotics.

GEBHARDT has been developing and producing load carriers for national customers as well as international global corporations for over 195 years and convinces with automated production technology and the highest quality standards in series production. As the market leader in the industry, we have very extensive know-how as a manufacturer of transport racks thanks to our many years of experience and produce load carriers for automotive in consistently high production quality.

GEBHARDT - Your specialist for transport and storage solutions in logistics!

Arrange consultation appointment Products in augmented reality