The EWPS wheel pallet

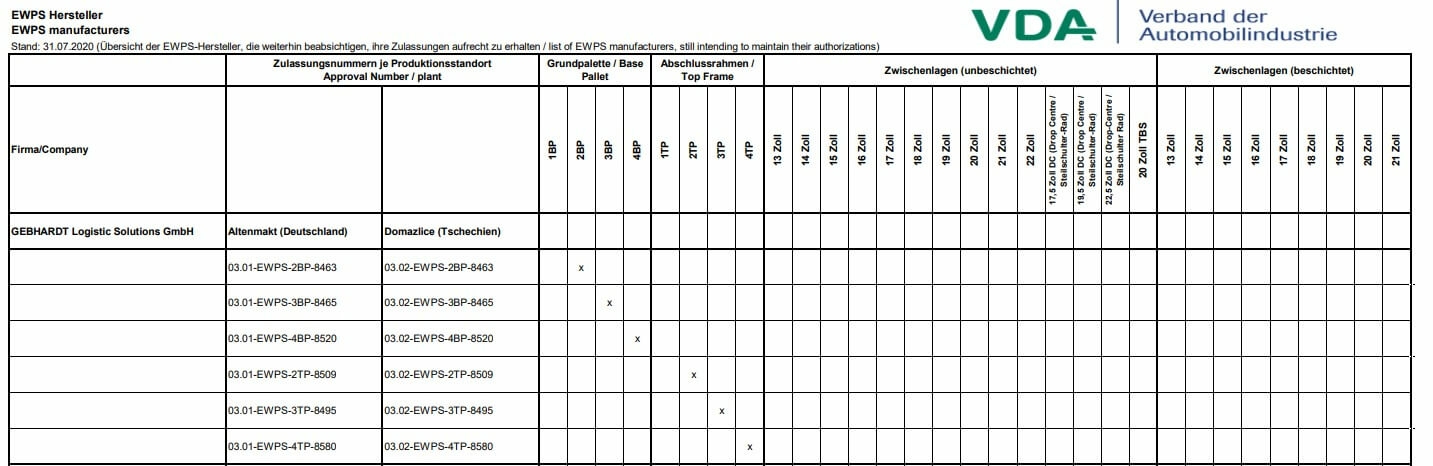

You want to supply leading companies in the automotive industry (OEMs) and are looking for a load carrier for wheels and rims certified by VDA and EUWA? Then GEBHARDT is the right choice for you! We are the only certified manufacturer for a total of three sizes of EWPS pallets in Europe.